Built in 2012, our first production hall, specialized in crafting, welding, and painting, is dedicated to the initial stages of production and offers extensive metal construction resources. Spanning 1,371 sqm, the facility includes a modern 148 sqm office building, home to a team of committed professionals.

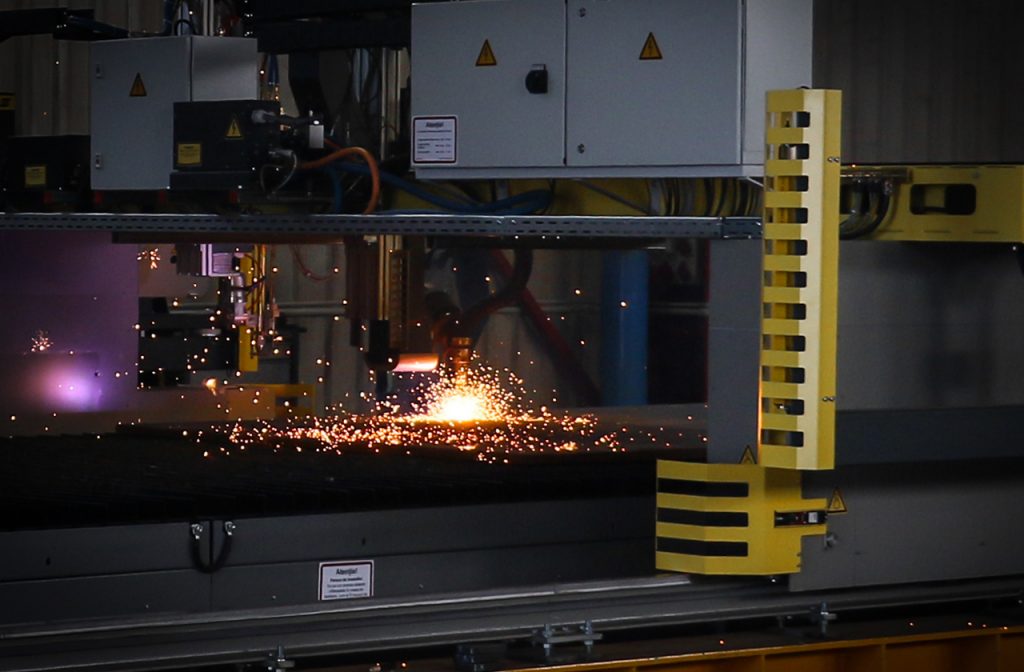

Plasma Cutting

We use ESAB Suprarex machine to cut the metal sheets, choosing between plasma jet and oxy gas. The plasma jet has the capacity to cut through a maximum of 40 mm thick metal sheets, and the oxy gas cuts through a maximum of 220 mm thick metal sheets.

Welding

At DMT Marine Equipment we understand that quality and safety are important when it comes to winch manufacturing. We are proud to comply with EN ISO 3834-2, a standard for welding quality management systems. Our Welding Procedure Specifications (WPS) and Welding Procedure Qualification Records (WPQR) are fully qualified according to the IACS member rules and regulations, BV, LR, DNV-GL, and ABS, demonstrating our adherence to the most rigorous industry norms. Our dedication to quality is backed by the expertise of an Internal NDT inspector level 2; NDT procedures approved by a level 3 inspector; an International/European Welding Engineer, and an International/European Welding Inspector.

Painting

Using advanced technologies and high-performance materials, we precisely apply coatings that ensure long-term durability and maintain the impeccable appearance of our equipment. Our painting process involves meticulous surface preparation, applying multiple protective layers, and rigorous quality inspection to guarantee that each piece of equipment meets and exceeds customer expectations in terms of durability and aesthetics.

Crafted with care, welded with precision, painted to perfection

At DMT Marine Equipment, we craft high-quality metal structures using advanced technology and skilled craftsmanship. Our skilled welders combine with precision each part, using different welding techniques to build strong, reliable structures. For the painting process, we use high-durability, corrosion-resistant epoxy systems tested according to industry standards, including ISO, SSPC, NACE, ASTM, and NORSOK. With attention to detail at every stage, we deliver equipment that performs exceptionally in even the most demanding conditions.